The eight disciplines (8D) model is a problem-solving framework that is used to identify, correct, and then eliminate problems. The eight disciplines model was first used by the U.S. Military in the Second World War. In more modern times, it was popularised in a 1987 Ford Motor Company manual on a team-oriented approach to problem-solving, based on eight sequential steps.

| Eight Disciplines (8D) Model | Description | Analysis | Implications | Applications | Examples |

|---|---|---|---|---|---|

| 1. Key Elements (KE) | The Eight Disciplines (8D) Model is a problem-solving methodology used in various industries, particularly in manufacturing and quality control. It consists of eight structured steps for identifying, analyzing, and resolving problems or issues within an organization or process. | – Understand and implement each of the eight disciplines sequentially to address a problem or issue effectively. – Ensure cross-functional teamwork and collaboration throughout the 8D process. – Apply data-driven analysis and root cause identification to resolve issues systematically. | – Provides a systematic approach for problem-solving and continuous improvement. – Encourages collaboration and cross-functional communication. – Promotes a data-driven and evidence-based problem-solving process. | – Quality control and process improvement in manufacturing. – Addressing product defects and quality issues. – Corrective and preventive actions for non-conformance. – Handling customer complaints and improving satisfaction. | Key Elements Example: A manufacturing company faces a recurring quality issue in one of its products. The 8D Model is used to systematically identify, analyze, and resolve the problem, involving cross-functional teams and data-driven analysis to find the root cause and implement corrective actions. |

| 2. D1: Establish the Team | D1 involves assembling a cross-functional team of individuals with diverse skills and expertise to address the identified problem. Team members should represent relevant departments and areas related to the issue. | – Identify team members with the necessary expertise and knowledge to address the problem. – Ensure clear roles and responsibilities for each team member. – Promote effective communication and collaboration within the team. | – Fosters collaboration and knowledge sharing among team members. – Increases the likelihood of identifying the root cause from diverse perspectives. – Encourages accountability and clear roles within the problem-solving process. | – Forming problem-solving teams in manufacturing and quality control. – Collaborative problem-solving in various industries. | D1 Example: A car manufacturer assembles a cross-functional team including engineers, quality control experts, and production line personnel to address a recurring issue with a specific car component. The team collaborates to identify and solve the problem. |

| 3. D2: Describe the Problem | D2 focuses on thoroughly understanding and describing the problem or issue. This step involves gathering data, documenting the problem’s symptoms, and defining the problem’s scope and boundaries. | – Gather relevant data and information related to the problem. – Document the problem’s symptoms, including when, where, and how they occur. – Define the problem’s scope to ensure a clear understanding of what needs to be addressed. | – Provides a comprehensive understanding of the problem’s nature and scope. – Helps in narrowing down potential root causes based on symptoms. – Ensures that the problem-solving team is aligned and aware of the issue. | – Identifying and documenting defects in manufacturing processes. – Investigating product or service quality issues. – Analyzing customer complaints to define problems. | D2 Example: A software development team experiences frequent system crashes in a specific module of their application. They gather data on when and how the crashes occur, document the error messages, and define the scope of the problem to address it effectively. |

| 4. D3: Develop a Interim Containment Plan | D3 involves implementing temporary measures to contain the problem and prevent it from causing further damage or issues. This step aims to stop the problem from worsening while the root cause is identified and addressed. | – Develop and implement interim measures to prevent the problem’s escalation. – Ensure that the containment plan is effective and mitigates immediate risks. – Continuously monitor the effectiveness of the containment measures. | – Prevents further damage or consequences while root cause analysis is conducted. – Offers immediate relief and protection for critical processes or products. – Allows for a focused and controlled problem-solving process. | – Implementing quick fixes to prevent defective products from reaching customers. – Temporary solutions for issues affecting manufacturing processes. – Controlling immediate risks in critical systems. | D3 Example: An electronics manufacturer discovers a malfunction in a component of a product that could lead to safety hazards. They implement a temporary fix to ensure that affected products are safe for use while they investigate the root cause of the issue. |

| 5. D4: Determine Root Cause | D4 involves conducting a thorough analysis to identify the root cause or causes of the problem. It requires data collection, data analysis techniques, and the use of various problem-solving tools to uncover the underlying reasons behind the issue. | – Collect and analyze data related to the problem’s symptoms and occurrences. – Apply problem-solving tools and techniques, such as fishbone diagrams or 5 Whys, to identify potential root causes. – Use statistical analysis to narrow down root cause candidates and validate findings. | – Identifies the underlying reasons behind the problem, allowing for targeted solutions. – Ensures that corrective actions are based on data and evidence. – May reveal systemic issues that need to be addressed for long-term improvement. | – Analyzing defects in manufacturing to pinpoint root causes. – Investigating software bugs to determine their origins. – Identifying the source of quality issues in a production process. | D4 Example: An automotive manufacturer experiences an increase in defective engine components. Through data analysis and the use of the 5 Whys technique, they discover that a specific supplier’s manufacturing process is causing the defects. |

| 6. D5: Develop Permanent Corrective Actions | D5 involves developing and implementing permanent corrective actions to address the root cause(s) of the problem. These actions are designed to prevent the problem from recurring in the future. | – Based on the identified root cause(s), develop specific corrective actions that will permanently resolve the issue. – Ensure that corrective actions are comprehensive and address all aspects of the problem. – Define a timeline for implementing corrective actions and monitoring their effectiveness. | – Addresses the fundamental causes of the problem, preventing its recurrence. – Promotes long-term process improvement and product quality. – Requires careful planning and implementation to ensure effectiveness. | – Implementing process changes to eliminate root causes of defects in manufacturing. – Revising software code to prevent recurring software bugs. – Updating quality control procedures to address identified issues. | D5 Example: A food processing company discovers that a specific ingredient supplier is the root cause of contamination issues. They develop and implement new supplier selection criteria and quality control measures to prevent future contamination problems. |

| 7. D6: Implement and Validate Corrective Actions | D6 involves putting the permanent corrective actions developed in D5 into action. It includes implementing process changes, updating procedures, and ensuring that the changes are effective in eliminating the problem. Validation ensures that the issue has been resolved successfully. | – Execute the planned corrective actions, including process changes, procedure updates, and any necessary training. – Monitor the implementation process closely to ensure that actions are carried out as intended. – Validate the effectiveness of the corrective actions by measuring and assessing key performance indicators (KPIs) and problem recurrence. | – Ensures that the corrective actions are effectively implemented. – Validates that the problem has been successfully resolved and does not recur. – Provides data and evidence to confirm the problem’s resolution. | – Verifying that process changes eliminate defects in manufacturing. – Assessing software performance to confirm bug resolution. – Monitoring quality control measures to ensure they prevent future issues. | D6 Example: A pharmaceutical company implements new quality control procedures and conducts training for its staff to eliminate contamination issues. They closely monitor the implementation process and track contamination incidents to validate the effectiveness of their corrective actions. |

| 8. D7: Prevent Recurrence and Recognize Team | D7 focuses on preventing the problem from recurring in the future by establishing preventive measures and controls. It also involves recognizing and celebrating the efforts of the problem-solving team for their contributions to resolving the issue. | – Develop and implement preventive measures, such as process controls and ongoing monitoring. – Establish a system for tracking and analyzing data to detect early signs of recurrence. – Recognize and appreciate the efforts of the cross-functional problem-solving team. – Celebrate the successful resolution of the problem. | – Ensures that the problem does not reoccur by implementing preventive controls. – Encourages a culture of continuous improvement and problem prevention. – Recognizes the contributions of team members, motivating them for future problem-solving efforts. | – Establishing quality control measures to prevent defects in manufacturing. – Monitoring software performance and conducting regular code reviews to avoid recurring bugs. – Recognizing the problem-solving team’s efforts and achievements. | D7 Example: An aerospace company implements strict quality control measures and ongoing monitoring to prevent defects in aircraft components. They also host a team appreciation event to celebrate the successful resolution of a critical safety issue. |

| 9. D8: Closure and Team Disbandment | D8 marks the closure of the 8D process. It involves formally closing the problem-solving effort, disbanding the cross-functional team, and documenting the results and lessons learned from the entire process. | – Formalize the closure of the 8D process, acknowledging the successful resolution of the problem. – Disband the problem-solving team and return team members to their respective roles. – Document the entire problem-solving process, including findings, actions taken, and outcomes. – Identify and document lessons learned for future reference and improvement. | – Officially concludes the problem-solving effort, ensuring that the issue has been successfully resolved. – Captures knowledge and insights gained during the process for future reference. – Allows team members to return to their regular roles or move on to new challenges. | – Concluding the resolution of product defects or quality issues. – Wrapping up the successful elimination of software bugs. – Documenting the results of customer complaint investigations. – Preparing a comprehensive report on the 8D process for organizational records. | D8 Example: A medical device manufacturer formally closes the 8D process after successfully resolving a critical product defect issue. They disband the problem-solving team, document the actions taken, and compile a comprehensive report detailing the problem’s resolution and lessons learned. |

Understanding the eight disciplines model

The model can be used in any industry that experiences difficult, critical, or recurring problems. It is particularly useful in process-oriented businesses that are looking to scale or are suffering growing pains as a result of scaling.

Problems in the model are tackled by addressing eight key disciplines that help identify (and provide corrective actions for) the root cause of a problem.

In the next section, we’ll take a look at each in more detail.

Using the eight disciplines model in practice

Applying the model to a real-world problem involves working through the following steps sequentially.

Discipline 1 – Assemble a team

The first step is to assemble a team with varying degrees of experience from different departments within the organization. By considering a diverse range of opinions, there is more chance the problem will be solved. A team leader should also be appointed to ensure a collaborative process.

Discipline 2 – Describe the problem

Using data or whatever information necessary, describe and define the problem by way of a problem statement. To arrive at this point, ask questions according to the 5W and 2H method:

- What is happening? In other words, what is the problem?

- Who is being affected by the problem?

- Where is it occurring?

- When – or how frequently – is the problem occurring?

- Why is the problem occurring?

- How does it take place?

- How much is the problem costing the business? Quantify in monetary terms where appropriate.

Discipline 3 – Formulate a containment plan

Containment involves isolating the problem from regular operations until permanent preventative action can occur. This step is especially important when customer or employee safety is at risk.

Many businesses stop here and confuse containment with a solution. However, addressing the symptoms of a problem are likely to lead to problem recurrence.

Discipline 4 – Identify the root cause

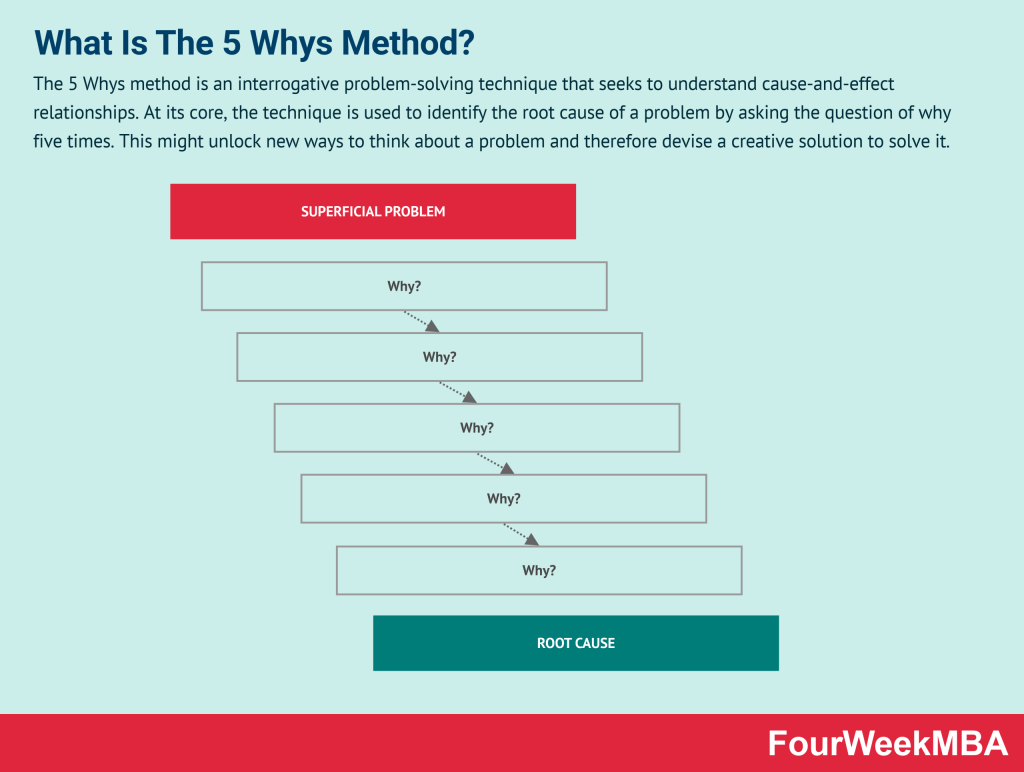

With the problem in containment, more resources can be devoted to root cause identification. There is a raft of methods available to achieve this, including the 5 Whys, Fishbone diagrams, and Pareto charts.

Regardless of the method chosen, root causes should wherever possible be backed up by hard quantitative data.

Discipline 5 – Analyse and verify corrective actions

With the data from the previous step, perform small-scale tests to verify whether the solution works in a real-world scenario. If the tests fail, go back to step four.

Discipline 6 – Implement corrective action

Once solutions from small-scale tests have been proven, they can then be implemented on a larger scale. When doing so, corrective actions must be monitored closely to determine their long-term viability.

Discipline 7 – Prevent recurrence

If a solution proves to be a long-term fix, then all systems and associated policies and procedures must be updated to reflect the change.

It’s also helpful to brainstorm how this solution might be applied to other problems – whether they be pre-existing problems or potential future problems.

Discipline 8 – Evaluate the process

Lastly, it’s important to thank each member of the team for their contribution. If a business is so inclined, it may choose to reward staff with a financial bonus or by mention in company announcements. This builds culture which results in engaged employees working collaboratively to identify and address critical problems.

Drawbacks of the 8D Model

Complexity and Time Consumption

The 8D process is thorough and structured, which can make it complex and time-consuming to implement, particularly for smaller or less complex issues.

Overdependence on Team Dynamics

The model relies heavily on effective team collaboration and communication. Any breakdown in team dynamics can significantly hinder the problem-solving process.

Expertise Required

Implementing the 8D Model requires a certain level of expertise in problem-solving methodologies, making it less accessible to teams without this training.

Potential for Over-Analysis

There is a risk of over-analysis or “paralysis by analysis,” where teams spend too much time on problem analysis and not enough on implementing solutions.

Limited Flexibility

The structured nature of the 8D Model may limit flexibility, making it less suitable for problems that require rapid, adaptive responses.

When to Use the 8D Model

In Quality Management

The 8D Model is particularly useful in quality management for systematically addressing and eliminating quality issues.

For Complex Problem Solving

It is ideal for complex problems where a detailed analysis is necessary to identify and address the root causes.

In Manufacturing and Engineering

In manufacturing and engineering sectors, the 8D Model is beneficial for improving products and processes by addressing recurring issues.

When Long-Term Solutions are Required

The model is best suited for situations where long-term, sustainable solutions are needed, rather than quick fixes.

What to Expect from Implementing the 8D Model

Systematic Problem Resolution

The 8D Model provides a systematic approach to problem-solving, ensuring thorough analysis and resolution.

Improved Product and Process Quality

Its use can lead to significant improvements in product and process quality by addressing issues at their root.

Enhanced Team Collaboration

The model fosters collaboration and effective communication within teams.

Development of Structured Problem-Solving Skills

Teams develop structured problem-solving skills that can be applied to various situations.

Long-Term Benefits

While time-consuming, the 8D Model offers long-term benefits by preventing the recurrence of problems, leading to more sustainable operations.

Key takeaways

- The eight disciplines model is a team-oriented problem-solving methodology for addressing recurring, critical, or difficult problems.

- The eight disciplines model was originally used by the U.S. Military during the Second World War. It was later adopted for use in business by Ford and today, can be used in virtually any industry.

- The eight disciplines model must be performed in sequential order so that problems can be temporarily isolated while a permanent solution is devised.

Key Highlights

- Definition: The Eight Disciplines (8D) Model is a problem-solving framework initially used by the U.S. Military in World War II and later popularized by Ford Motor Company in 1987. It is employed to identify, correct, and eliminate problems in various industries.

- Understanding 8D:

- Addresses recurring, critical, or complex problems.

- Useful in process-oriented businesses undergoing scaling or growth.

- Consists of eight sequential disciplines to identify and resolve root causes.

- Applying the 8D Model:

- Assemble a Team: Create a diverse team with varied experience across departments and appoint a team leader.

- Describe the Problem: Define the problem using the 5W and 2H method (What, Who, Where, When, Why, How, How much).

- Formulate a Containment Plan: Isolate the problem from regular operations to prevent further impact.

- Identify the Root Cause: Use methods like 5 Whys, Fishbone diagrams, or Pareto charts to pinpoint root causes.

- Analyze and Verify Corrective Actions: Test potential solutions through small-scale trials.

- Implement Corrective Action: Apply proven solutions on a larger scale while closely monitoring progress.

- Prevent Recurrence: Update systems, policies, and procedures to reflect the change and brainstorm its broader applicability.

- Evaluate the Process: Acknowledge team members’ contributions, possibly with rewards, fostering a collaborative culture.

- Key Characteristics:

- The 8D Model is a problem-solving methodology to address complex issues.

- Initially used by the U.S. Military and later adopted by Ford.

- Follows a sequential approach for isolating, identifying root causes, testing solutions, and preventing recurrence.

| Related Frameworks | Definition | Focus | Application |

|---|---|---|---|

| Eight Disciplines (8D) Model | A problem-solving methodology used to identify, correct, and prevent recurring problems or non-conformances in processes or products. The 8D process involves eight sequential steps, including defining the problem, forming a team, root cause analysis, implementing corrective actions, and preventing recurrence. | Focuses on systematically addressing and resolving problems by following a structured approach, emphasizing teamwork, data-driven analysis, and preventive measures to ensure long-term solutions and continuous improvement. | Quality Management, Problem-solving, Continuous Improvement |

| Six Sigma | A data-driven methodology for process improvement, focusing on minimizing variability and defects to achieve near-perfect quality in products or services. It follows a structured approach of Define, Measure, Analyze, Improve, and Control (DMAIC) to identify and eliminate process defects and inefficiencies. | Focuses on reducing process variation and defects to improve quality and performance, employing statistical methods and rigorous problem-solving techniques. | Process Improvement, Quality Management, Operational Excellence |

| Lean Management | A management philosophy and set of principles aimed at maximizing customer value while minimizing waste and inefficiencies in processes. It emphasizes continuous improvement, respect for people, and the elimination of non-value-added activities through the application of Lean tools and techniques. | Focuses on streamlining processes, eliminating waste, and optimizing flow to enhance efficiency and customer value, with a strong emphasis on employee involvement and continuous improvement. | Process Optimization, Waste Reduction, Operational Excellence |

| PDCA Cycle (Plan-Do-Check-Act) | A four-step iterative problem-solving method used for continuous improvement of processes and products. PDCA involves planning (identifying problems and proposing solutions), doing (implementing solutions), checking (evaluating results), and acting (standardizing successful processes or making further improvements). | Focuses on iterative problem-solving and continuous improvement by systematically testing, implementing, and refining solutions to achieve desired outcomes and maintain quality standards. | Continuous Improvement, Quality Management, Problem-solving |

| Root Cause Analysis (RCA) | A systematic approach to identifying the underlying causes of problems or failures in processes or products. RCA involves analyzing events or issues to determine their root causes and implementing corrective actions to prevent recurrence. | Focuses on identifying the fundamental reasons behind problems or incidents to develop effective solutions and prevent future occurrences, often using techniques like the “5 Whys” or fishbone diagrams. | Problem-solving, Quality Management, Incident Investigation |

| Failure Mode and Effects Analysis (FMEA) | A structured approach to identifying and mitigating potential failure modes or risks in processes, products, or systems. FMEA involves systematically analyzing potential failure modes, their causes and effects, and prioritizing preventive actions to minimize risks and improve reliability. | Focuses on proactively identifying and addressing potential failure modes or risks in processes or products to prevent defects, enhance quality, and increase reliability, often conducted during design or process development stages. | Risk Management, Quality Assurance, Product Development |

| Total Quality Management (TQM) | A management approach focused on continuous quality improvement across all aspects of an organization. TQM emphasizes customer satisfaction, employee involvement, process improvement, and the use of data-driven decision-making to achieve excellence in product or service quality. | Focuses on embedding quality principles and practices throughout the organization, fostering a culture of continuous improvement and customer focus, and striving for excellence in all aspects of operations. | Quality Management, Continuous Improvement, Customer Satisfaction |

| DMAIC Methodology | A problem-solving methodology used in Six Sigma projects, consisting of five phases: Define, Measure, Analyze, Improve, and Control. DMAIC provides a structured approach to identify, analyze, and improve processes by reducing variation and defects. | Focuses on defining project goals, measuring process performance, analyzing root causes, implementing improvements, and controlling outcomes to achieve measurable and sustainable results in process improvement initiatives. | Six Sigma, Process Improvement, Quality Management |

Connected Decision-Making Frameworks

Failure Mode And Effects Analysis

Related Strategy Concepts: Go-To-Market Strategy, Marketing Strategy, Business Models, Tech Business Models, Jobs-To-Be Done, Design Thinking, Lean Startup Canvas, Value Chain, Value Proposition Canvas, Balanced Scorecard, Business Model Canvas, SWOT Analysis, Growth Hacking, Bundling, Unbundling, Bootstrapping, Venture Capital, Porter’s Five Forces, Porter’s Generic Strategies, Porter’s Five Forces, PESTEL Analysis, SWOT, Porter’s Diamond Model, Ansoff, Technology Adoption Curve, TOWS, SOAR, Balanced

Read Next: Mental Models, Biases, Bounded Rationality, Mandela Effect, Dunning-Kruger Effect, Lindy Effect, Crowding Out Effect, Bandwagon Effect, Decision-Making Matrix.

Read More: